Over 40 years of design and manufacture of excavator fronts

An inhouse design team with more experience on bespoke excavators and specialist applications than many of the OEM’s

Produced the BOTH the worlds heaviest demolition excavator, based on a Caterpillar 5130 weighing in at 260 tonnes AND the worlds highest demolition excavator, based on a Hitachi EX1200 souring some 70 metres into the air !!

ISO 9001 certification

Winner of numerous design and innovation awards, including World Demolition Awards 2017 in the innovation category

FAE stress analysis

3D modelling

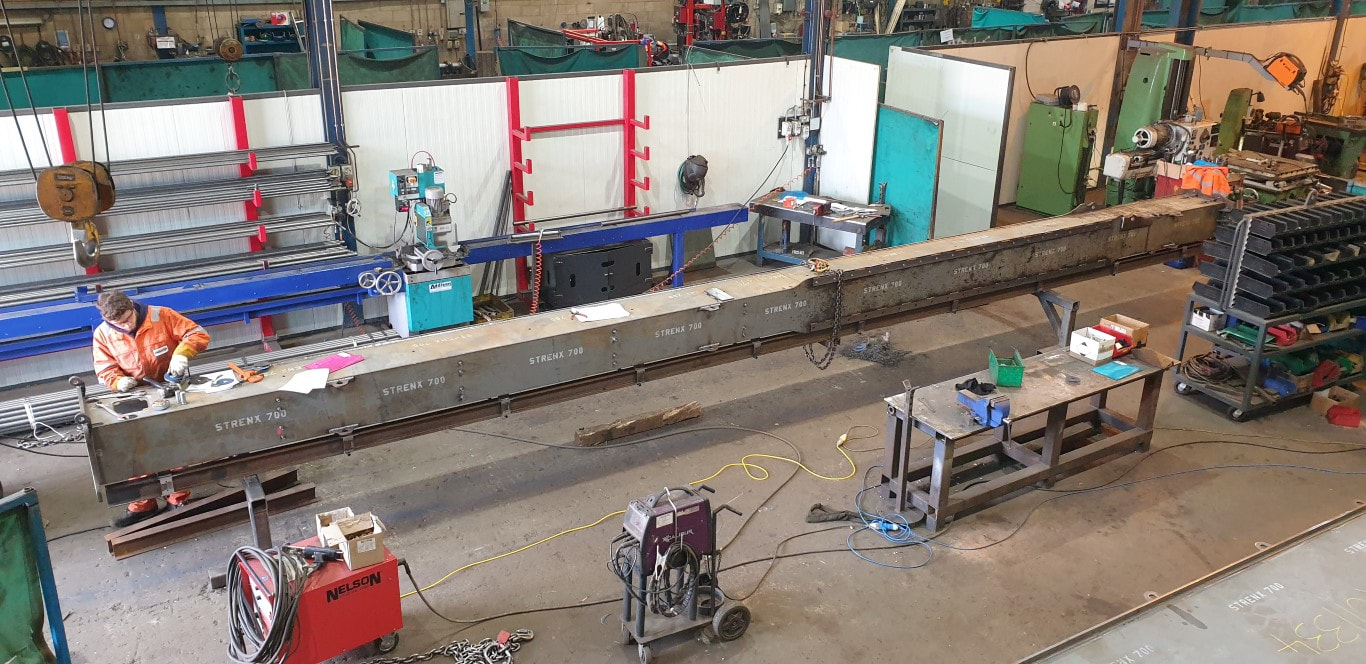

UK sole certified user of steel SSAB ‘Strenx’

The strongest and lightest material on the market

Stand alone material cutting shop with 20 tonne overhead crane to take oversize steel sheets – this means less welded joins in the finished excavator arm, therefore increasing its strength

Flame cutting upto 200mm

Plasma

Laser

Cold saw for round bar

Robot sub arc welding table 20m – long arm sections can be welded in one uninterrupted pass in sub arc conditions, resulting in the strongest join possible

Line boring rig 18m - long arm sections can be bored from one position, resulting in the most accurate bores and therefore longer lasting pins / bushes in the finished product

Well equipped CNC machine shop, using the latest Haas rigs from USA – these state of the art machines produce components with fantastic dimensional tolelences, result in long lasting components on the finished arm

Large assembly shop and yard

In house design and manufacture of all hydraulic cylinders, case hardened pins, wiring looms – no reliance on outside suppliers, if you make something yourself, then you know its done right !!

An inhouse design team with more experience on bespoke excavators and specialist applications than many of the OEM’s

Produced the BOTH the worlds heaviest demolition excavator, based on a Caterpillar 5130 weighing in at 260 tonnes AND the worlds highest demolition excavator, based on a Hitachi EX1200 souring some 70 metres into the air !!

ISO 9001 certification

Winner of numerous design and innovation awards, including World Demolition Awards 2017 in the innovation category

FAE stress analysis

3D modelling

UK sole certified user of steel SSAB ‘Strenx’

The strongest and lightest material on the market

Stand alone material cutting shop with 20 tonne overhead crane to take oversize steel sheets – this means less welded joins in the finished excavator arm, therefore increasing its strength

Flame cutting upto 200mm

Plasma

Laser

Cold saw for round bar

Robot sub arc welding table 20m – long arm sections can be welded in one uninterrupted pass in sub arc conditions, resulting in the strongest join possible

Line boring rig 18m - long arm sections can be bored from one position, resulting in the most accurate bores and therefore longer lasting pins / bushes in the finished product

Well equipped CNC machine shop, using the latest Haas rigs from USA – these state of the art machines produce components with fantastic dimensional tolelences, result in long lasting components on the finished arm

Large assembly shop and yard

In house design and manufacture of all hydraulic cylinders, case hardened pins, wiring looms – no reliance on outside suppliers, if you make something yourself, then you know its done right !!

Customers

Vertical Divider

|

First Square Equipment Ltd

The Throstle, Allendale, Northumberland, United Kingdom NE47 9DQ +44 (0) 1434 618 784 +44 (0) 7985 203 952 Email sales@firstsquare.com First Square designs and manufactures specialist equipment for the construction industry

Telescopic excavator dipper stick / teledipper Other specialist excavator fronts and attachments Bespoke excavator conversions Our equipment is compatible with all major brands of machines including JCB, Caterpillar, Komatsu, Volvo, Liebherr, Hyundai, Doosan, and many others We have our own in house design and production facilities, so we are able to customise one of our existing products to suit your requirements, or alternatively build a bespoke product to fulfill your needs Foreign Language PagesVertical Divider

|

Customers

|

First Square Equipment Ltd - Registered Office: The Throstle, Allendale, Northumberland, NE47 9DQ. Registered Number: 05423484. Registered in England & Wales.

E.&O.E. © COPYRIGHT 2015.

E.&O.E. © COPYRIGHT 2015.